In the automotive industry, busbars play a critical role in facilitating the distribution of electrical power within vehicles, enabling efficient energy management and supporting the operation of various electronic components. As automotive manufacturers continue to innovate and electrify their vehicle fleets, the demand for advanced busbar solutions is on the rise. This report provides a comprehensive analysis of the automotive busbar market, including its size, share, industry analysis, trends, and growth prospects for the year 2032.

Market Size and Share:

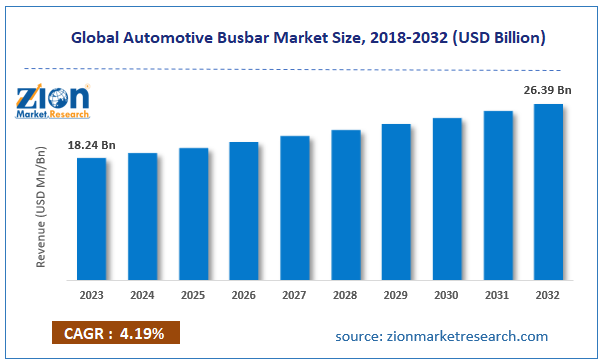

The global automotive busbars market was valued at $18.24 billion in 2023 and is expected to reach $26.39 billion by 2032, growing at a CAGR of roughly 4.19% from 2024 to 2032.

The automotive busbar market encompasses a wide range of products, including copper busbars, aluminum busbars, and laminated busbars, designed to meet the diverse needs of vehicle electrification. As of the latest data, the market size for automotive busbars is significant, with contributions from automotive OEMs, busbar suppliers, and technology providers. The market share is distributed among established players in the automotive electronics industry, as well as emerging startups and niche manufacturers specializing in busbar solutions.

Industry Analysis:

- Electrification Trends: The increasing focus on vehicle electrification, driven by regulatory mandates, environmental concerns, and advancements in battery technology, is driving the demand for automotive busbars. Electric vehicles (EVs), hybrid electric vehicles (HEVs), and plug-in hybrid electric vehicles (PHEVs) require robust busbar systems to efficiently distribute power between the battery pack, electric motors, inverters, and other electronic components.

- Rising Demand for Advanced Electronics: The proliferation of advanced electronic systems in modern vehicles, including infotainment systems, advanced driver-assistance systems (ADAS), and electric powertrains, is driving the need for high-performance busbar solutions. Automotive busbars play a crucial role in supporting the increased power requirements and thermal management challenges associated with these electronic systems.

- Focus on Lightweighting and Space Optimization: Automotive manufacturers are increasingly focused on lightweighting initiatives and space optimization to improve vehicle efficiency and performance. Lightweight materials such as aluminum and laminated composites are being used to design compact and efficient busbar solutions that meet the stringent weight and space constraints of modern vehicles.

- Integration of Smart Technologies: The integration of smart technologies such as sensors, embedded electronics, and predictive analytics into automotive busbars is enabling real-time monitoring, diagnostics, and predictive maintenance capabilities. Smart busbar systems can detect faults, monitor temperature variations, and optimize power distribution, enhancing overall vehicle reliability and safety.

Market Trends:

- High-Voltage Busbars for EVs: With the proliferation of electric vehicles, there is a growing demand for high-voltage busbar solutions capable of handling the increased power requirements of EV drivetrains and battery systems. High-voltage busbars enable efficient power distribution at voltages exceeding 400 volts, supporting the transition to long-range EVs with fast-charging capabilities.

- Advanced Thermal Management: Thermal management is a critical consideration in automotive busbar design, particularly in high-power applications such as electric vehicles. Advanced thermal management techniques, including liquid cooling, phase-change materials, and thermal interface materials, are being integrated into busbar designs to dissipate heat effectively and maintain optimal operating temperatures.

- Integration of Power Electronics: Automotive busbars are increasingly integrated with power electronics components such as inverters, converters, and DC-DC converters to minimize power losses and improve energy efficiency. Integrated power modules combine busbars with semiconductor devices in compact and modular packages, enabling simplified assembly and enhanced performance.

- Adoption of Flexible Busbar Technologies: Flexible busbars made of copper foil or laminated materials are gaining traction in automotive applications due to their flexibility, lightweight design, and space-saving characteristics. Flexible busbars enable greater design flexibility, easier installation, and improved reliability compared to traditional rigid busbar solutions, particularly in electric and hybrid vehicle architectures.

Growth Forecast for 2032:

The automotive busbar market is poised for significant growth and innovation in the coming years, driven by:

- Continued investments in electric vehicle development and infrastructure to support the transition to zero-emission mobility solutions.

- Technological advancements in materials science, manufacturing processes, and thermal management techniques to meet the evolving requirements of automotive busbar applications.

- Collaboration and partnerships between automotive OEMs, busbar suppliers, and technology providers to co-develop innovative busbar solutions and drive standardization across the industry.

- Integration of advanced connectivity, sensing, and data analytics capabilities into automotive busbars to enable intelligent power management and predictive maintenance functionalities.

Conclusion:

In conclusion, the automotive busbar market presents lucrative opportunities for manufacturers, suppliers, and technology providers to innovate and capitalize on the growing demand for efficient and reliable power distribution solutions in vehicles. By leveraging lightweight materials, advanced thermal management techniques, and smart technologies, automotive busbar stakeholders can address the evolving needs of electric and hybrid vehicle architectures and contribute to the advancement of sustainable and connected mobility solutions in the automotive industry.